Drilling sludge pit as a disposal site for drilling waste

Despite the undoubted success in the field of new technologies, the situation with power generation has not changed for many years. Oil and gas were and remain the main energy resources. Therefore, neither the political tensions around oil and gas production are decreasing, nor the economic long-term strategies are deviating too far from volumes and development strategies of the fields. Consequently, the environment will still be threatened by the same pollution factors from oil production as before.

Despite the undoubted success in the field of new technologies, the situation with power generation has not changed for many years. Oil and gas were and remain the main energy resources. Therefore, neither the political tensions around oil and gas production are decreasing, nor the economic long-term strategies are deviating too far from volumes and development strategies of the fields. Consequently, the environment will still be threatened by the same pollution factors from oil production as before.

The cumulative effect of this impact should also be taken into account: currently, the negative environmental effects of drilling of new wells and the generation of new waste are imposed on the impact of previously accumulated and disposed drilling and oil production waste.

The constantly deteriorating global environmental situation urgently calls for stricter environmental policies, in particular in the area of drilling waste management.

Sludge pits are objects of waste disposal. The design, construction and registration of a waste disposal facility, which includes sludge pits (sludge storage), in reality takes about a year and a half – this period is sometimes longer than the entire life of the well cluster. In addition, the need to design their own landfill for drilling wastes falls heavily on small oil producing companies’ side.

Thus, the method of pitless drilling comes to the fore. With this method, drilling sludge are disposed of directly on a well pad or in the vicinity of a specialized development site. This method, applied at some industrial facilities, allows not only not to accumulate new drilling waste, but also to dispose of old sludge pits, which have been poisoning the surrounding soil for decades due to the lack of adequate waterproofing.

Main technologies of drilling waste and drilling cuttings disposal

Drilling waste utilization creates significant challenges for the industry due to the diversity of drilling sludge composition. The amount of drilling cuttings from one well is conditionally taken as 120% of the total well volume (not taking into account the volume of flushing media). The chemical and mineralogical composition depends on both the type of mud and the type of rock to be drilled. The particle size distribution also depends on both the rock and the type of drilling mud. From the aforesaid it is not difficult to understand that there is no and cannot be a single effective method of drilling waste management.

Metods | Description |

Thermal |

|

Mechanical |

|

Chemical |

|

Biological |

|

Below is the experience of sludge pit remediation based on the regulations of one of the main Russian oil producers. According to the regulations, the recycling of drilling waste consists of the following stages:

- separation of the liquid phase of waste from solid one by natural (sedimentation) or forced (centrifugation or other type of dewatering) method;

- clarification;

- pumping of the liquid phase;

- curing of residue, drilling cuttings and waste mud;

- backfilling of the pit with soil.

Clarification in the pit is carried out by reacting with aluminium (iron) sulphide. The prepared coagulant is sprayed on the surface of the pit. After settling for 1-2 days, the liquid phase is collected from the surface of the pit by a pump through the suction, held on the surface of the pit by a floating structure. The liquid phase in the barn is then neutralized and the oil enriched upper layer is pumped into the reservoir. The dewatered remnant of the drilling cuttings is solidified with cement.

Pumping back into the formation after cleaning is a very common technology for recycling drilling cuttings and drilling waste. However, stringent requirements of manufacturers of equipment for preparation and injection of drilling mud dictate the requirements to the initial raw materials and it is not always economically feasible to comply with them. Besides, injection into the formation is allowed only under certain geological conditions of the field.

Thermal methods of drilling sludge and drilling mud treatment from the table above are the most effective due to their universality. At present the market is gradually growing the supply of equipment for thermal processing of drilling waste.

- Driling sludge preparation unit

- Uploading of drilling sludge to TDP for processing

- Technical soil – product of drilling waste processing

For example, the service company BT-PROMOTKHODY LLC has been successfully engaged in industrial waste disposal for several years already, specializing in drilling waste associated with the production of crude oil, natural (associated) gas and gas condensate, using equipment produced by IPEC – high-performance units TDP-2-2000 and TDP-2-800. Initially they were single-reactor continuous pyrolysis units TDP-2, then, after confirming the feasibility of the technological process and economic benefits to the Customer, technical re-equipment was carried out: the improved high-performance units TDP-2, equipped with additional reactors, were delivered, which increased the overall productivity. Such a solution was the most optimal for high-watered sludge.

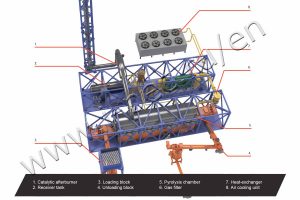

Continuous pyrolysis technology at TDP-2 for processing of drilling wastes

The TDP-2 unit is a continuous pyrolysis reactor, where the feed is fed and conveyed by a screw system. The discharged liquid is condensed and purified, the dry residue is a technical soil with high salt content, suitable for pits backfilling and reclamation of the territory. The thermal treatment process is isolated from the environment and its safety (and the safety of personnel) is automatically maintained by the Emergency Protection Controller through a system of sensors located at key points in the process.

The equipment operates in a fully automatic mode, without requiring operator intervention. All data of technological stages are displayed on the touch screen. The automation control system (ACS) involves several access levels, in the debugging mode the technician can control all the units and all devices from the screen. Operator mode does not require such capacities. In the process of recycling from class 3-4 waste (moderately hazardous waste/low hazardous waste), the operating organization receives class 5 waste (almost non-hazardous waste). Since the composition of the waste fed to TDP-2 unit can be heterogeneous in fractional composition and can be supplied from different sources, the quality of the technical soil (unit product) was checked by laboratory on a monthly basis during the year. The analytical data confirm the stable composition and environmental safety of the products in the form of inert dry residue during the processing of any oil-containing wastes of 3-4 class. The minimum content of oil products and heavy metals is also confirmed by chemical analysis protocols. The content of sulphur dioxide and carbon monoxide in the waste gases is below the detection limit of the measuring method and, therefore, does not represent a hazard to the environment. For the rest of the indicators, the emissions are also in line with the established values. The test protocols are available on request from IPEC.

The equipment operates in a fully automatic mode, without requiring operator intervention. All data of technological stages are displayed on the touch screen. The automation control system (ACS) involves several access levels, in the debugging mode the technician can control all the units and all devices from the screen. Operator mode does not require such capacities. In the process of recycling from class 3-4 waste (moderately hazardous waste/low hazardous waste), the operating organization receives class 5 waste (almost non-hazardous waste). Since the composition of the waste fed to TDP-2 unit can be heterogeneous in fractional composition and can be supplied from different sources, the quality of the technical soil (unit product) was checked by laboratory on a monthly basis during the year. The analytical data confirm the stable composition and environmental safety of the products in the form of inert dry residue during the processing of any oil-containing wastes of 3-4 class. The minimum content of oil products and heavy metals is also confirmed by chemical analysis protocols. The content of sulphur dioxide and carbon monoxide in the waste gases is below the detection limit of the measuring method and, therefore, does not represent a hazard to the environment. For the rest of the indicators, the emissions are also in line with the established values. The test protocols are available on request from IPEC.

Positive experience of using TDP-2 Thermal Deconposition Units for treatment of drilling waste proves the prospects of it’s universal application at oil and gas fields. This solution will ensure the transition to pitless drilling, thus relieving the producing company of the need to equip and register the waste disposal facility, as well as its subsequent costly operation.

To get acquainted with the model range of TDP-2, please visit the catalog of the Thermal Deconposition Plants.

The article “Drilling waste treatment at production sites: pitless drilling – on guard of environment!” was published in ECOINJ magazine, issue 20, 2020.

When using the material/any part of it, reference to the authorship and website (www.i-pec.ru) is mandatory