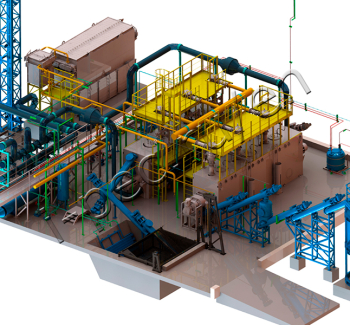

Thermal Decomposition Plant TDP-2-3000

Technical characteristics

3000 kg/hour* capacity

continuous operation batches per day

180 kW power consumption

380 volt voltage

- oil sludge

- drilling sludge

- acid sludge

-

TDP-2-3000 is designed for processing of the following waste types (raw materials):

- drilling waste

- oil sludge

- drill cuttings

- drilling muds

- acid tar

- oil-soaked soils

- oil emulsions

- waste oils.

The process is based on low temperature pyrolysis, which is the process of thermal destruction of feedstock into low molecular weight components in oxygen deficient environment. As a result of processing of raw materials, marketable products are obtained, which can be used for their intended purpose.

TDP-2-3000 plant features modernized reactor.

Use of the products derived from raw materials containing hydrocarbons:

- pyrolysis (furnace) fuel =>

=> is used as a fuel, including TDP-2-3000 operation fuel; - dry residue of hazard class 4 (non hazardous) =>

=> is used for construction and reclamation purposes; - pyrolysis gas =>

=> is used for the operation of the plant.

ADVANTAGES OF TANDEM VERSION OF TDP-2-3000

(2 reactors in one process train):- reduces operating costs for personnel and also dimensions of the operation area due to laying out the process in one train;

- increases the performance by serving the main line with one set of auxiliary equipment;

- optimization of the technological solution.

ADVANTAGES OF THE NEW REACTOR DESIGN

Due to the modernized design the efficiency of heat exchange surface is increased:

- fuel consumption thus is cut considerably;

- reactor capacity is increased.

* Capacity depends on the content of oil products and water in the feedstock, calculated as part of the pre-design study.

-

Stage 1. Continuous failsafe supply of raw materials

Waste oil products from the receiving hopper are fed to pyrolysis reactor No.1:

=> solid waste – by screw conveyors;

=> pasty and liquid products – by sludge pump.Stage 2. Thermal decomposition process

- In the pyrolysis reactor No.1 heated by burners, which are installed in the furnace, thermal decomposition (pyrolysis) of the raw material in an inert atmosphere begins.

- Hot solid residue from chamber No.1 is transferred by conveyors to pyrolysis reactor No.2, where additional thermal destruction of the residual organics take place by exposure in oxygen free environment.

Start-up fuel is supplied by gravity to the liquid fuel burners from the fuel tank; after process stabilization and reaching self-supporting point the unit switches to the fuel gas* produced within the process and used by gas burners.

Stage 3: Condensation and separation processes

Thermal destruction products in the form of vapor-gas mixture from pyrolysis chambers are fed to the condensation unit (common pipeline for reactors No.1 and No.2), where they are cooled and separated into liquid fraction and pyrolysis gas:

Thermal destruction products in the form of vapor-gas mixture from pyrolysis chambers are fed to the condensation unit (common pipeline for reactors No.1 and No.2), where they are cooled and separated into liquid fraction and pyrolysis gas:=> The liquid fraction is discharged into a tank and pumped periodically to the tank farm.

=> Pyrolysis gas is fed to the burner devices.Stage 4. Flue gas removal

- A catalytic afterburner is installed in the gas duct before the gas outlet to the heat exchanger, where CO (carbon monoxide) and residual organic compounds are catalytically oxidized to neutral CO2 and water.

- The flue gas is removed from the furnace chambers by an exhauster.

Stage 5. Discharge of solid residue

Dry residue is discharged by conveyors to the ash collector, and then to the ash receiver, from where it is periodically discharged by conveyor to dump trucks.

* depending on the calorific value of the raw material.