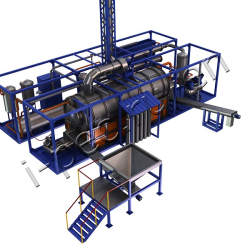

Continuous Thermal Decomposition Plant (TDP-2-800)

Technical characteristics

800-1500 kg/h capacity

continuous operation batches per day

35 kWh power consumption

380 volt voltage

- oil sludge

- drilling sludge

- acid sludge

- coal, coal-tar

-

The process is based on low-temperature pyrolysis, involving the use of heat to thermally decompose the feedstock in the condition of oxygen deficit. Marketable products are obtained as a result of the processing of raw materials.

Usage of the product derived from hydrocarbon (organic) materials:

- Boiler fuel =>

=> used for its intended purpose

=> used to obtain gasoline, diesel fuel fraction when additional equipment (distillation column) is supplied

- Dry residue is used for local, construction and reclamation needs

- Heat produced during the process (about 150 kWh) is used for the room heating

- Pyrolysis gas is used for the plant operation

Usage of the product derived from water-based materials:

- Distilled water =>

=> used for drilling mud preparation

=> used as process water when installing the system of additional purification

=> used as drinking water when installing the system of additional purification and mineralization

- Dry residue is used for local, construction and reclamation needs

- Heat of the process (about 150 kWh) is used for the room heating

ADVANTAGES OF TDP-2-800:

- minimum air emissions

- unique exclusive technology for continuous processing of drill cuttings, regardless of their composition

- low energy consumption – 35 kW

- PRODUCTIVITY – 800-1500 kg/h

- rational use of a valuable resource – the energy component of waste (used as an alternative energy source)

- lack of supply/handling of water is provided by a cooling system closed loop

- perfect automated control system operated automatically or manually from the operator’s control panel

- mobility:

– plant is installed on its own chassis

– overall dimensions – two 40 ft. containers

- operators – 2 people

-

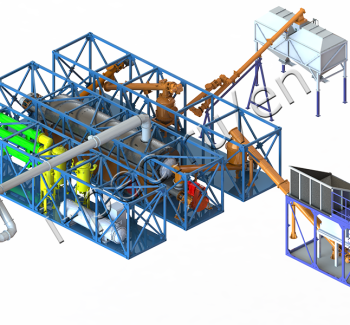

TDP-2-800 process description:

1. Raw material are fed to the pyrolysis chamber on continuous mode:

=> solid waste by screw conveyor;

=> liquid waste by pump.

2. Boiler fuel or diesel oil is self-fed to the burner from fuel tank.

3. Air is fed to the burner by compressor, which is switched to the pyrolysis gas after the process is stabilized.

4. Vapor-gas mixture from pyrolysis chamber comes to the condensation system through gas filter.

5. The further cooling is carried out in a heat exchanger.

6. Water is cooled in air coller unit or in chiller.

7. The cooled mix enters the separator where it split up on fractions:

=> pyrolysis oil is directed to the receiver tank;

=> pyrolysis gas is directed to the buster burners.

8. Solid residue is discharged by screw conveyor, cools in hopper and transported to the storage bin.