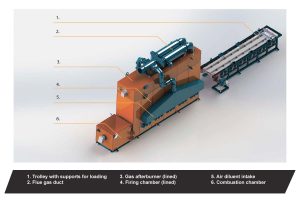

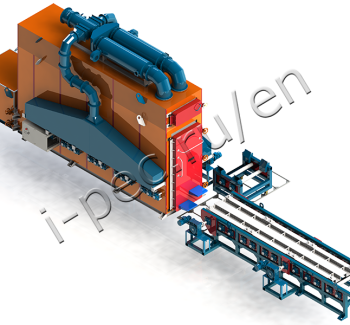

Thermal Cleaning Plant (TCP)

Technical characteristics

300 kg/h capacity

3 batches per day

15 kWh power consumption

380 volt voltage

Purpose

Removal of scale, corrosion, leftovers of old coatings/paint materials, oils and emulsions, petroleum residues:

:- oil sludge

-

The process is based on low-temperature pyrolysis, involving the use of heat to thermally decompose the feedstock in the condition of oxygen deficit, cleaning the surfaces of metal products from organic.

TCP ADVANTAGES:

- effective cleaning of various types of metal from all types of organic pollutants

- complete removal of persistent corrosion and deposits

- elimination of the metal products integrity damage

- environmental safety of technology => releases of hazardous substances to the environment are excluded

- lack of material costs for the purchase of components of cleansing mixtures

- minimum amount of waste at the outlet

- low energy intensity

-

TCP Process Description:

- Metal products placed on a tray are loaded into the firing chamber.

- Metal products heating takes place in the firing chamber.

- Reaching the operating temperature.

- Flue gases formed in the process of burning metal products enter the afterburning chamber.

- After cooling, the flue gases are removed by the exhauster through a chimney.